Memories may fade over time, but your clothing doesn't have to.

We all have a particular piece of clothing that through aesthetic, sentimentality or unparalleled comfort finds its way into our hearts as a favorite. From band t-shirts to school spirit hoodies, making sure the color stands out, doesn’t fade, or stain the other parts of your wardrobe, isn’t something usually considered until you find yourself as the unhappy owner of pink everything after a red shirt snuck its way into your load of whites. Luckily, there are well established test methods that allow textile manufacturers to showcase the durability and stainability of their dyes and pigments, providing consumers the ability to make objective decisions regarding performance.

First: Some Basics

Color fastness, sometimes referred to as washing fastness, refers to a material’s color’s resistance to fading or running. Essentially, this is the term used to provide consumers a scale to help understand how good or bad a color behaves once printed onto a textile like cotton. The degree of color fading or running is determined through the Gray Scale for Color Change, while the degree of color staining (or ability to stain other types of fabric) is determined through the Gray Scale for Staining. Both scales and the test methods used to evaluate the various dyes and pigments are written and published by the American Association of Textile Chemists and Colorists (AATCC), with the intent to provide a harmonized system for the testing and quantification of color performance in textiles.

What this boils down to is an easy-to-understand scale ranging from 1 to 5, where 5 indicates there is no change in color and 1 indicates the most change in color. In years prior, these values were determined visually, but in order to eliminate any bias, the use of instrumentation such as a spectrophotometer is now employed.

So Why Not Just Make Everything a 5?

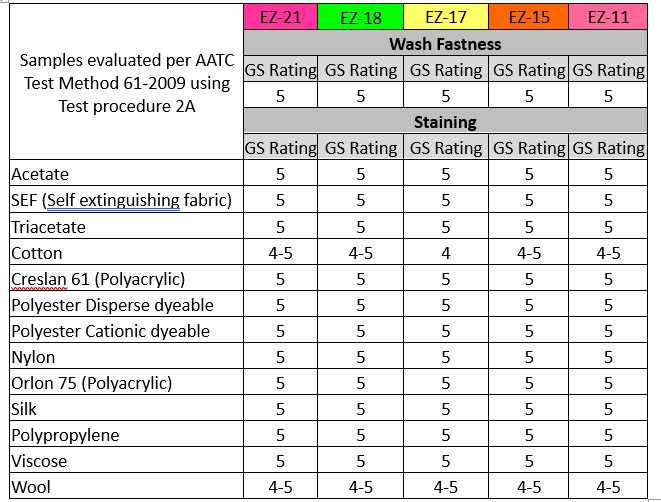

Even with the most visually brilliant pigment in the world, if one does not use a compatible binder system, there is quite literally no way to put it on a textile and have it behave as intended. Chemically speaking the affinity of pigments towards cotton is extremely low compared to dyes, so the process of coloring the fabric is facilitated through dispersing said pigment into a self-linking acrylic-based polymer system. This binder system will then help the pigment adhere to the fabric and allow color to be added. For the most part the components of this binder system can be broken down into the binding agent, a thickening agent, a defoamer, a fixing-agent, humectant and if necessary, a softening agent. The complexity behind determining chemical makeup and concentration of the various components can be quite a daunting task, even more so when you realize that most chemical binder systems contain formaldehyde. Here at DayGlo, not only have we developed a completely formaldehyde free fluorescent pigment for textile use, but we also generated consumer data using a formaldehyde free binder system as well. Our Ezentus series or EZ pigments combined with Helizarin binding reagents offer incredible wash fastness as well as superb staining, as seen below. Of the 13 different fabric types only two were found to have any amount of staining from the EZ pigment There is no longer a need to sacrifice performance in order to meet the increasing demand of removing formaldehyde from your product with DayGlo pigments.

A video describing in more detail the chemistry behind a pigment binder system: https://www.youtube.com/watch?v=ParqI-_5lVg